Wholesale Fastener Distributor

Fasteners

PSI specializes in Stainless Steel (S.S), G.I, M.S, and High Tensile Bolts, Nuts, Washers and Screws of many varieties, such as:

-

Hexagonal Head Bolts

-

Flange Bolts

-

Metric Hex Bolts

-

Allen Cap Head Bolts

-

Threaded Rods

-

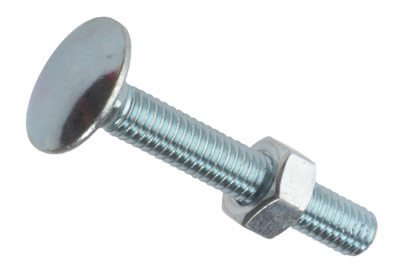

Carriage Bolts

-

U Bolts

-

Square Head Bolts

-

Shoulder Bolts

-

Plow Bolts

-

Full Thread Bolts

-

Hex Nuts

PSI specializes in many variations of strengths and styles as well as coatings of all fasteners. PSI deals with all grades, including Grade 2,Grade 5, Grade 8, 304 stainless, 316 stainless, A36, Grade 55, Grade 107 and can also provide custom-made bolts based on drawings. PSI also sells threaded rods, studs, and various sizes of bolts and nuts at the most competitive prices.

Fastener Examples Call For More Options

Hexagonal Head Bolts

Hex bolts are known by many different names, but they all have a hexagonal head that is designed to be driven by a wrench. Bolts and screws are the terms used to describe them all. Because of the threading, they are one-of-a-kind. These bolts have a shoulder beneath the head and are partially threaded. Up to the hexagonal head, tap bolts are fully threaded. The design of a hex bolt’s head is its distinguishing feature, and it is from this that they acquire their name.

Flange Bolts

Hexagonal heads on flange bolts allow them to be driven with a wrench. The design of a flange bolt’s head is its distinguishing feature, and it is from this that they acquire their name. The bolt’s “flange” is a built-in (integral) washer. This washer is serrated to operate as a lock washer in Imperial sizes. Flange bolts come in two thread types: full thread and partial thread. The threading is determined by the bolt lengths. Fully threaded flange bolts are threaded to the underside of the flanged head, while partially threaded flange bolts feature a shoulder.

Metric Hex Bolts

Metric hex bolts are made of stainless steel grade A2 or zinc-plated steel. The hexagonal head on all hex bolts is designed to be driven by a socket or wrench. Metric hex cap screws, metric tap bolts, and metric hex flange bolts are all available.

Allen Cap Head Bolts

The Allen bolts we source are widely utilized in the mechanical and heavy engineering industries. These nuts do not loosen when torque and vibrations are applied, and they provide locking action by deforming elastically. For the Allen Bolt, we use high-quality mild steel as the basic material, which gives them strength, longevity, and good grip. Galvanization is used to electroplate all of the nuts to prevent them from oxidizing.

Threaded Rods

Threaded Rods are commonly regarded as the quickest and most cost-effective way of manufacturing uniform, smooth, precise threads with exceptional physical properties. Non-threading activities like as burnishing, knurling, and rolling of helical and annular grooves of various shapes are also possible with this method. Threaded Rods create exterior threads using hardened steel rollers. The rolls’ working surfaces have a thread shape that is the polar opposite of the thread to be created.

Carriage Bolts

The shank of a carriage bolt is capped by a short square part under the bolt’s head, and the head is domed or countersunk. When the nut is tightened, the square section grabs the item being fastened, preventing the bolt from rotating. Wood panels or boards are frequently fastened to masonry or to one another with carriage bolts. When the square shank of the bolt is placed into a round hole in wood or a square hole in a metal strap, the unthreaded square shank pulls into the wood, forming a tight bond.

U Bolts

We provide a high-quality assortment of U Bolts that are known for their durability and effectiveness. These bolts are made utilizing high-quality raw materials and cutting-edge technology in accordance with our clients’ drawings and printing.

Square Head Bolts

Square Head Bolts are similar to Hex Cap Screws, except instead of a 6-sided hexagonal head, they have a 4-sided square head. The square head allows for a more comfortable wrench grip and a bigger bearing area for gripping. Bolts and screws are the same thing, and they’re both supposed to be driven with a wrench. Square Head Bolts can either be partially or fully threaded, depending on your needs.

Shoulder Bolts

Shoulder Bolts are machine screws that have a shoulder between the thread and the part’s head. The non-threaded shoulder of the bolts extends out of the surface of the application site once mounted, allowing them to be used as dowels, shafts for moving parts, axles, or guides for sliding assembly pieces. They can be installed with a socket (Allen) driver or by hand.

Plow Bolts

Plow bolts feature a flat head that sits flush once placed, similar to carriage bolts. They have a flat head because they are frequently employed in situations where a domed head would be seen. The flat head prevents the bolt from wearing down and helps it to last longer on the scouring surface (area where the head of the bolt would be exposed to high wear). They can be taken out simply unscrewing the nut from the bolt.

Full Thread Bolts

Tap bolts, also known as hex tap bolts, are hex head bolts that have a full thread (tip to beneath head) independent of diameter or length.

Whereas Standard Hex Cap Screws are partially threaded with a shoulder beneath the fastener hex head. The equation to determine the thread length on those are twice the diameter of the bolt plus 1/4”of additional thread.

Hex Nuts

Hex nuts are utilized in a variety of fastening situations. When mechanically attaching materials, these nuts are frequently used with screws and bolts. If the screw you’re using is smaller than 1/4-20 (for example, 8-32 or 10-24), you should use and look for hex machine screw nuts. Hex nuts are offered in fine thread and coarse thread, with sizes ranging from 1/4-20 to 3.

Nuts and Bolts FAQs

Nuts:

A nut is a fastener that has a threaded hole in it. To secure numerous parts together, nuts are nearly typically used in conjunction with a mating bolt. The two partners are kept together by a combination of their threads’ friction (with small elastic deformation), a slight stretching of the bolt, and compression of the parts to be held together.

Lock washers, jam nuts, specialist adhesive thread-locking fluid such as Loctite, safety pins (split pins) or lockwire in conjunction with castellated nuts, nylon inserts (nyloc nut), or slightly oval-shaped threads may be used in applications where vibration or rotation may force a nut loose.

Square nuts, like bolt heads, were the first to be created and were once the most prevalent, owing to their ease of fabrication, especially by hand. The greater length of each side allows a spanner to be applied with a larger surface area and more leverage at the nut, which is rare today[when?] due to the reasons stated below for the preference of hexagonal nuts. They are occasionally used in some situations when a maximum amount of torque and grip is needed for a given size: the greater length of each side allows a spanner to be applied with a larger surface area and more leverage at the nut.

The hexagonal shape is the most frequent design nowadays, for the same reasons as the bolt head: six sides provide a good granularity of angles for a tool to approach from (excellent in tight locations), but more (and smaller) corners are subject to being rounded off. The next side of the hexagon is only one sixth of a spin away, and grip is ideal. Polygons with more than six sides, on the other hand, do not provide the required grip, and polygons with fewer than six sides take longer to rotate completely. Other customized shapes, such as wingnuts for finger adjustment and captive nuts (e.g. cage nuts) for inaccessible places, are available for specific applications.

Bolts:

It’s difficult to tell the difference between a bolt and a screw. Bolts are designed to enter through an unthreaded hole in a component and be fixed with the help of a nut, although such a fastener can be used without a nut to tighten into a threaded component such as a nut-plate or tapped housing, according to Machinery’s Handbook. Screws, on the other hand, are utilized in components that have their own thread or are cut with their own internal thread. This definition allows for ambiguity in the description of a fastener depending on the purpose it is used for, and the terms screw and bolt are widely used to refer to the same or different fasteners by different persons or in various nations.

Bolts are frequently utilized in bolted joints. This is a combination of the nut gripping the joint axially and the bolt shank acting as a dowel, pinning the joint against sideways shear stresses. As a result, many bolts have a plain unthreaded shank (known as the grip length), which results in a superior, stronger dowel. The existence of an unthreaded shank has been cited as a distinguishing feature of bolts vs. screws, however this is more of a byproduct of their use than a distinguishing feature.

A screw is a fastener that creates its own thread in the component being secured. When the thread is tapered (as with traditional wood screws), the use of a nut is required, or when a sheet metal screw or other thread-forming screw is used. To put the joint together, you must constantly turn a screw. During assembly, many bolts are held in place by a tool or a non-rotating bolt design, such as a carriage bolt, and only the corresponding nut is turned.

1210 C N Council Rd, Oklahoma City, OK 73127 Phone: 405-782-0380 Fax: 405-782-0387